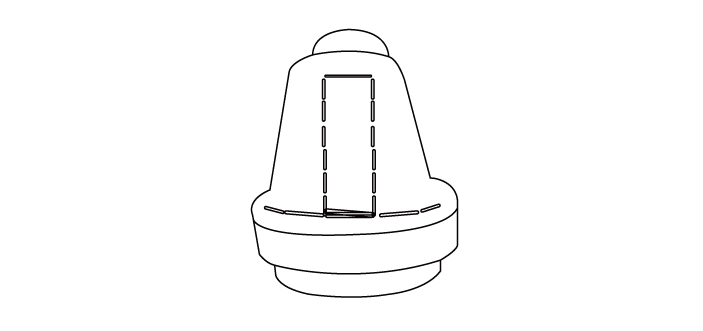

Derby Shoeskit

What's in side of Derby Soles kit

What's in side of Derby Soles kit

- Outsoles

- Insoles

- Instruction Paper

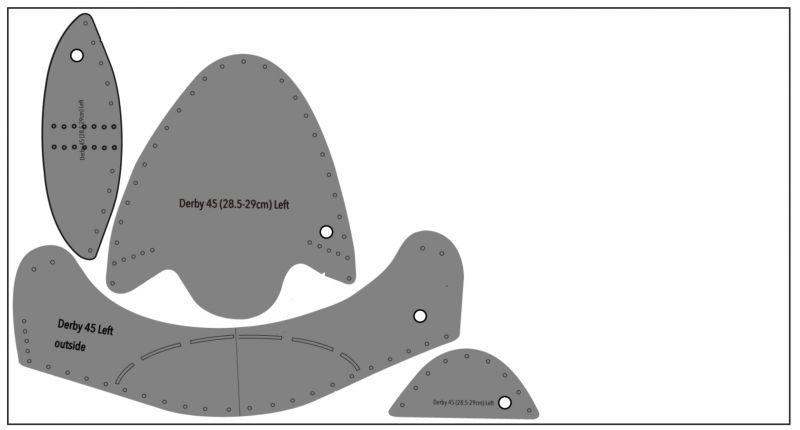

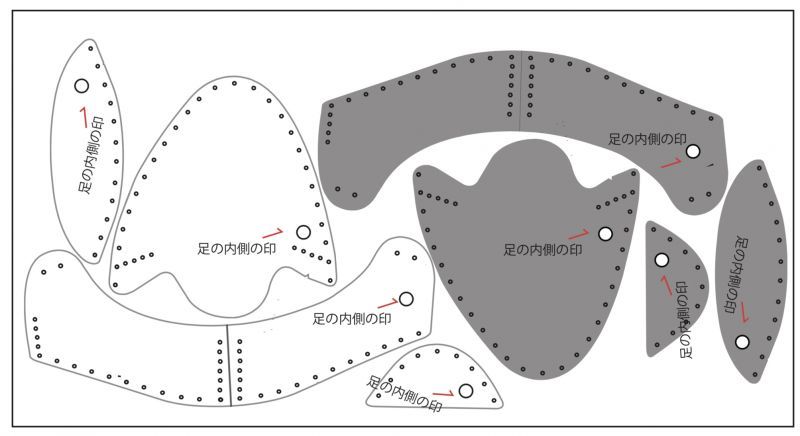

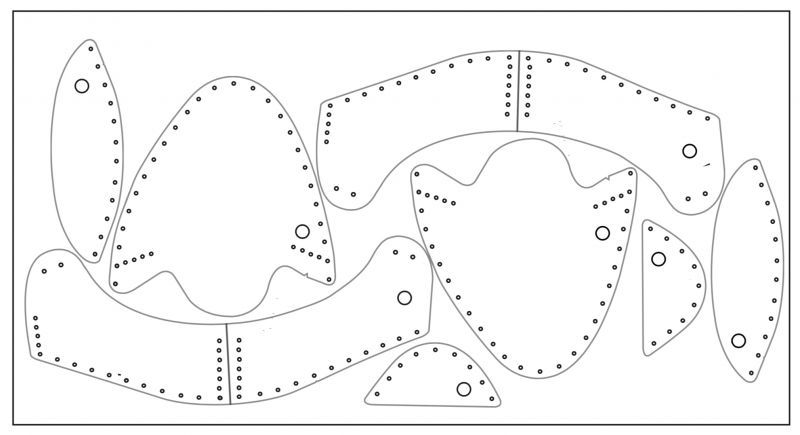

- Patterns

- Thread

- Materials

- Shoe laces

- Eyelets

If you only need soles and ThreadSoleskitPlease check

Step1

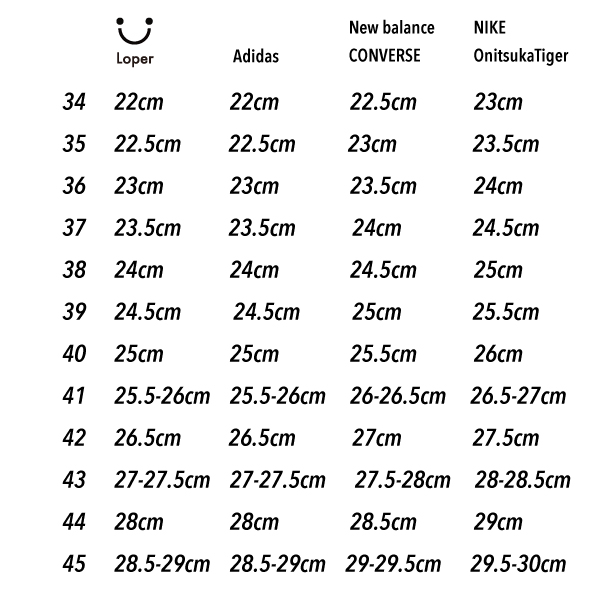

Choose your size

The size may vary slightly depending on the brand and model. Please refer to the table below and compare it with the size of the shoes you usually wear.

Step2

Select the main material. It is about 330cm x 620cm.

Black Leather

Combination tanned almighty leather that boasts outstanding stability.

The amount of chrome is suppressed, and tannins are probably included in the dyeing stage to give a moderate elasticity.

The more you wear it, the more it will become familiar to your feet.

It is a material developed as leather for making baseball gloves. The raw leather uses the finest steyr from North America. Glove tanning is performed for the purpose of not breaking the fibers, and it is lighter than conventional glove leather, wrinkle-resistant, and the original flexibility and moist texture of leather is perfect for making shoes.

Tochigi Leather

It is a leather made by Tochigi Leather Co., Ltd., which is said to be the highest peak in Japan, and is specially manufactured (vegetable tannin tanned leather) and finished with almost no surface processing.

It is supple and durable, and its tasteful changes over the years are highly evaluated not only in Japan but all over the world.

Traditionally, Nume leather has the image of being a hard material that is difficult to commercialize. Therefore, Tochigi leather was created as Nume leather that has both softness and durability by a unique manufacturing method.

Step3

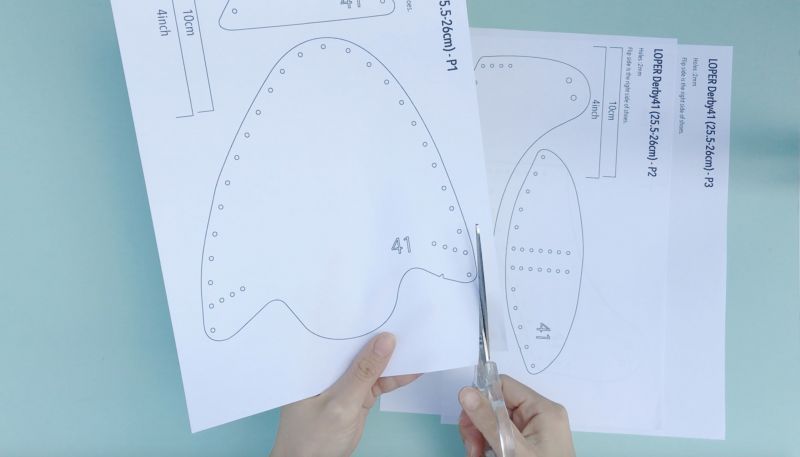

Cut out the patterns with scissors or sharp knife.

Step4

Punch holes in the patterns

Step5

Trace the patterns on the material with a pen.

Step6

The printed side of the patterns are for the left shoe, flip the pattern to make the right shoe.

It's good to write on each patterns, 'right' or 'left' to prevent the mistake.

Step7

Cut out the materials along the trace line and punch the holes.

Step8

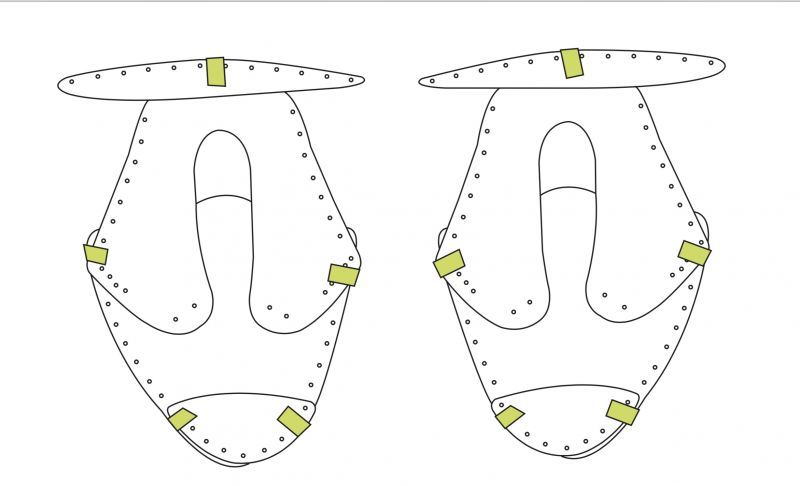

After cutting all the patterns, temporarily fix the left and right parts with masking tape at the correct positions.

Step9

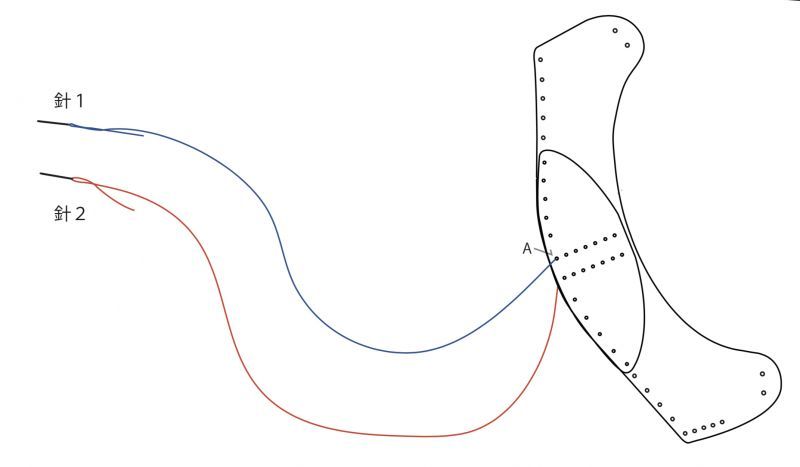

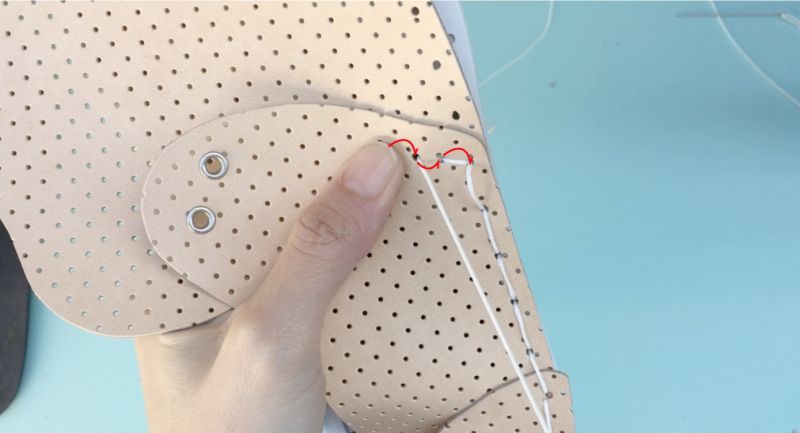

Pass the needle through both ends of the attached thread.

Insert a needle in position A and thread the threads until both threads are the same length.

Sew to point D with needle 1.

After sewing needle 2 to point D, stab needle 1 into position D on the sole.

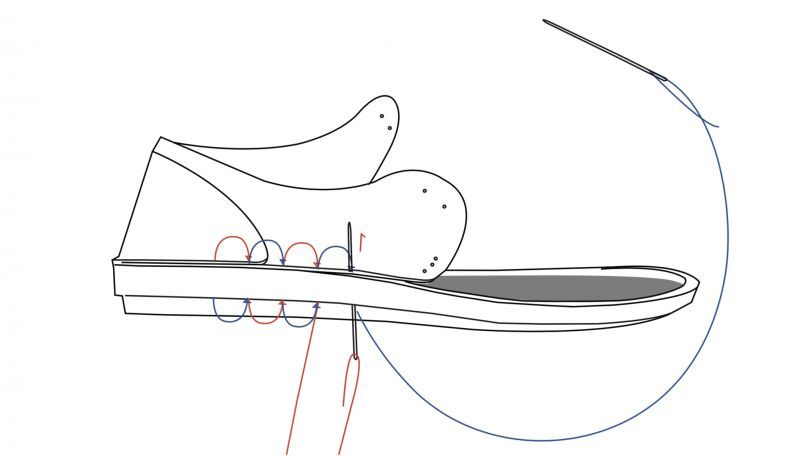

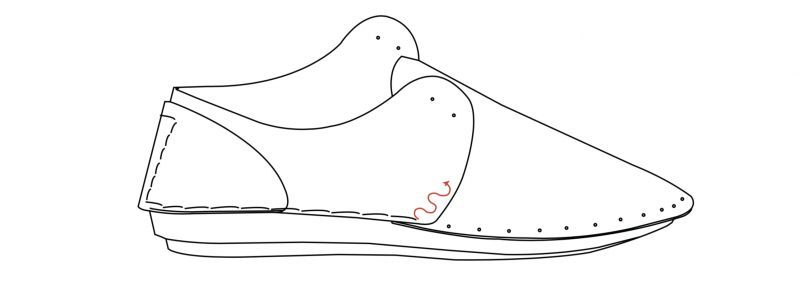

Step10

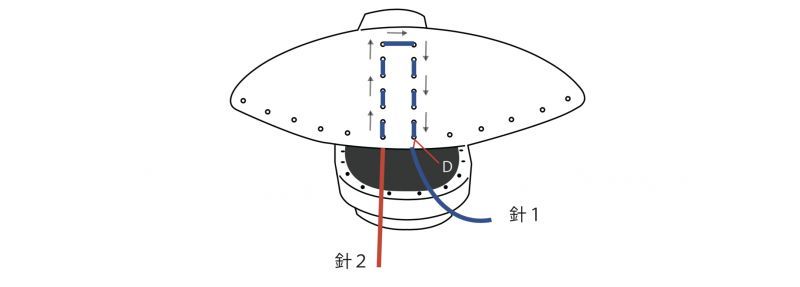

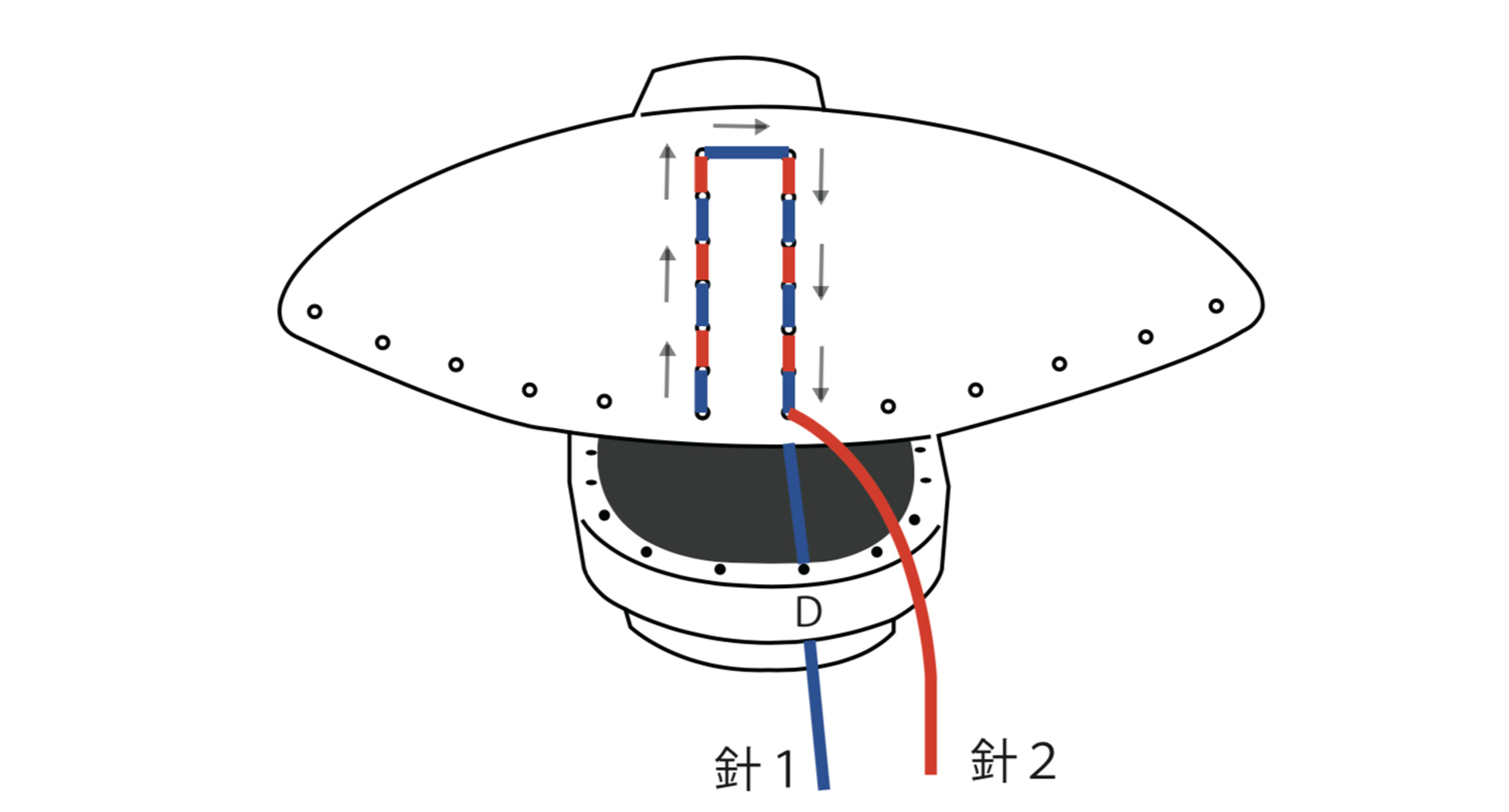

The upper and sole will be connected with a 'saddle stitch'.'Saddle stitching' is a way to sew alternately with two needles as shown in the picture below.

On the side stitch part, sew up and back down with one needle.

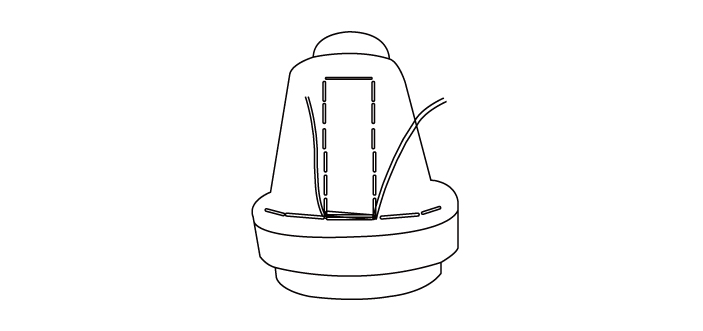

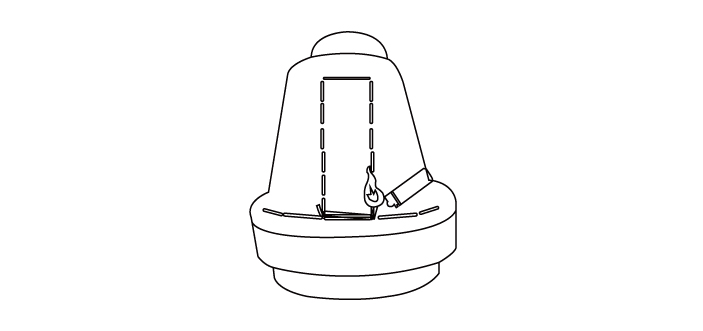

For the final cleanup, sew both threads twice.

Put out the thread at the position shown in the picture. Cut the thread at about 5 mm.

Firewith a lighter the thread so that it cannot be unraveled.

Put the insole and put the string through to complete!

Customer's voice

Better DIY

Our dream for the near future is to develop kids size LOPER's so kids can make their own shoes too.

Shoe manufacturing often is a unhealthy and harmful industry, for workers and environment.

Stop buying shoes and start making them :)

It's fun to do and such a great feeling to walk on your selfmade shoes!

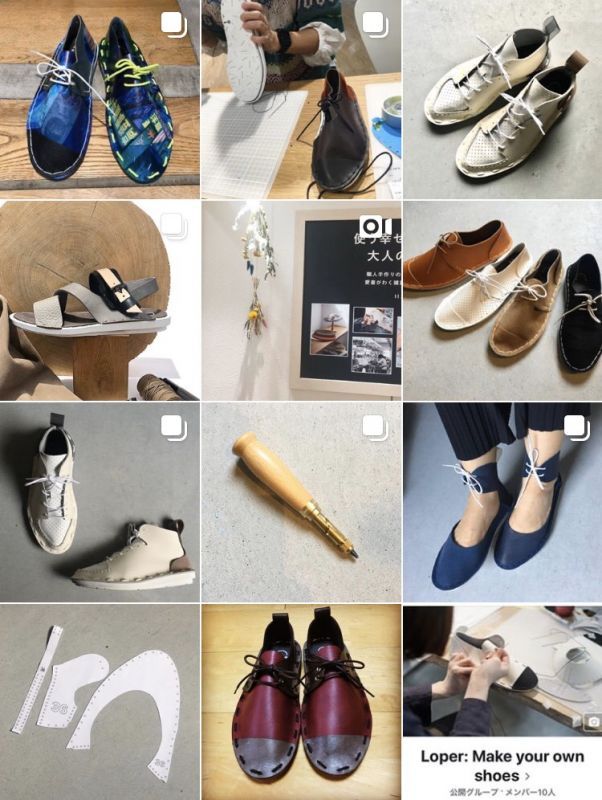

@loper_shoes Instagram

Facebook Loper